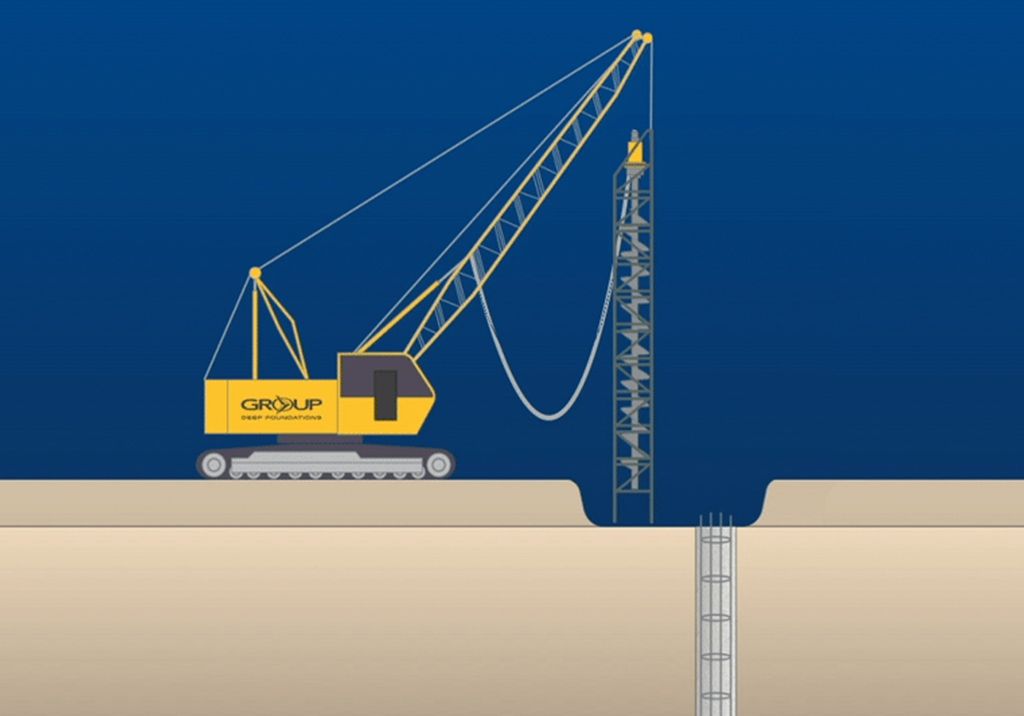

While some foundation systems are specified for particular environments, topographies and soil conditions, a designer’s preference is usually the deciding factor. That’s particularly true when it comes to auger cast piles, as many engineers consider it to be a superior, more efficient foundation system.

Shannon Bergeron, a GROUP Contractors Superintendent since 2007, says many engineers feel auger casts create a better foundational footprint. “When you drill into the ground and fill it with grout, you’re eliminating any voids in the hole,” Bergeron says. “In other words, you have more side bearing pressure, more static pressure and more friction. That makes it the preferred pile for many engineers.”

Of course, there are other factors to consider. With auger casts, the contractor must precisely sequence grout deliveries as well as maneuver grout trucks within an existing industrial facility. “You have 90 minutes to use the grout on that truck,” Bergeron says. “If you don’t use it within 90 minutes of the time it was batched, you lose that batch.” The site can also become somewhat muddy, depending upon the weather and other conditions. Other times, the composition of the soil might make it difficult to stabilize a hole.

Nonetheless, many projects are ideally suited for auger cast. Projects within existing industrial plants typically use the system, as industrial vessels can be highly sensitive to vibration (a disadvantage of driven pile systems). There are also certain geological conditions more conducive to auger cast, such as sandy soils or clay strata. “In those situations, we get more production out of drilling the piles than driving precast,” Bergeron says.

[ssba-buttons]

While some foundation systems are specified for particular environments, topographies and soil conditions, a designer’s preference is usually the deciding factor. That’s particularly true when it comes to auger cast piles, as many engineers consider it to be a superior, more efficient foundation system.

Shannon Bergeron, a GROUP Contractors Superintendent since 2007, says many engineers feel auger casts create a better foundational footprint. “When you drill into the ground and fill it with grout, you’re eliminating any voids in the hole,” Bergeron says. “In other words, you have more side bearing pressure, more static pressure and more friction. That makes it the preferred pile for many engineers.”

Of course, there are other factors to consider. With auger casts, the contractor must precisely sequence grout deliveries as well as maneuver grout trucks within an existing industrial facility. “You have 90 minutes to use the grout on that truck,” Bergeron says. “If you don’t use it within 90 minutes of the time it was batched, you lose that batch.” The site can also become somewhat muddy, depending upon the weather and other conditions. Other times, the composition of the soil might make it difficult to stabilize a hole.

Nonetheless, many projects are ideally suited for auger cast. Projects within existing industrial plants typically use the system, as industrial vessels can be highly sensitive to vibration (a disadvantage of driven pile systems). There are also certain geological conditions more conducive to auger cast, such as sandy soils or clay strata. “In those situations, we get more production out of drilling the piles than driving precast,” Bergeron says.